|

WHAT WE STAND FOR The latest innovation at Milteco are individual, turnkey complete solutions for pendulum bucket elevators. Here you will find concentrated food expertise and the latest, long-lasting technology. All of this combined with the best all-round service from an experienced and dynamic team.

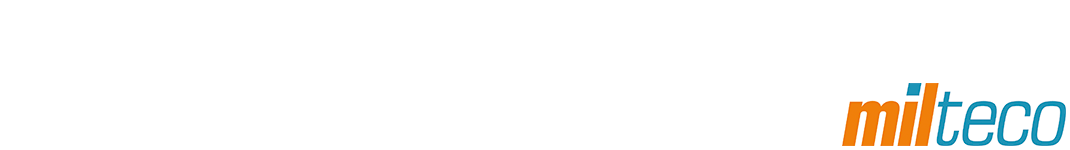

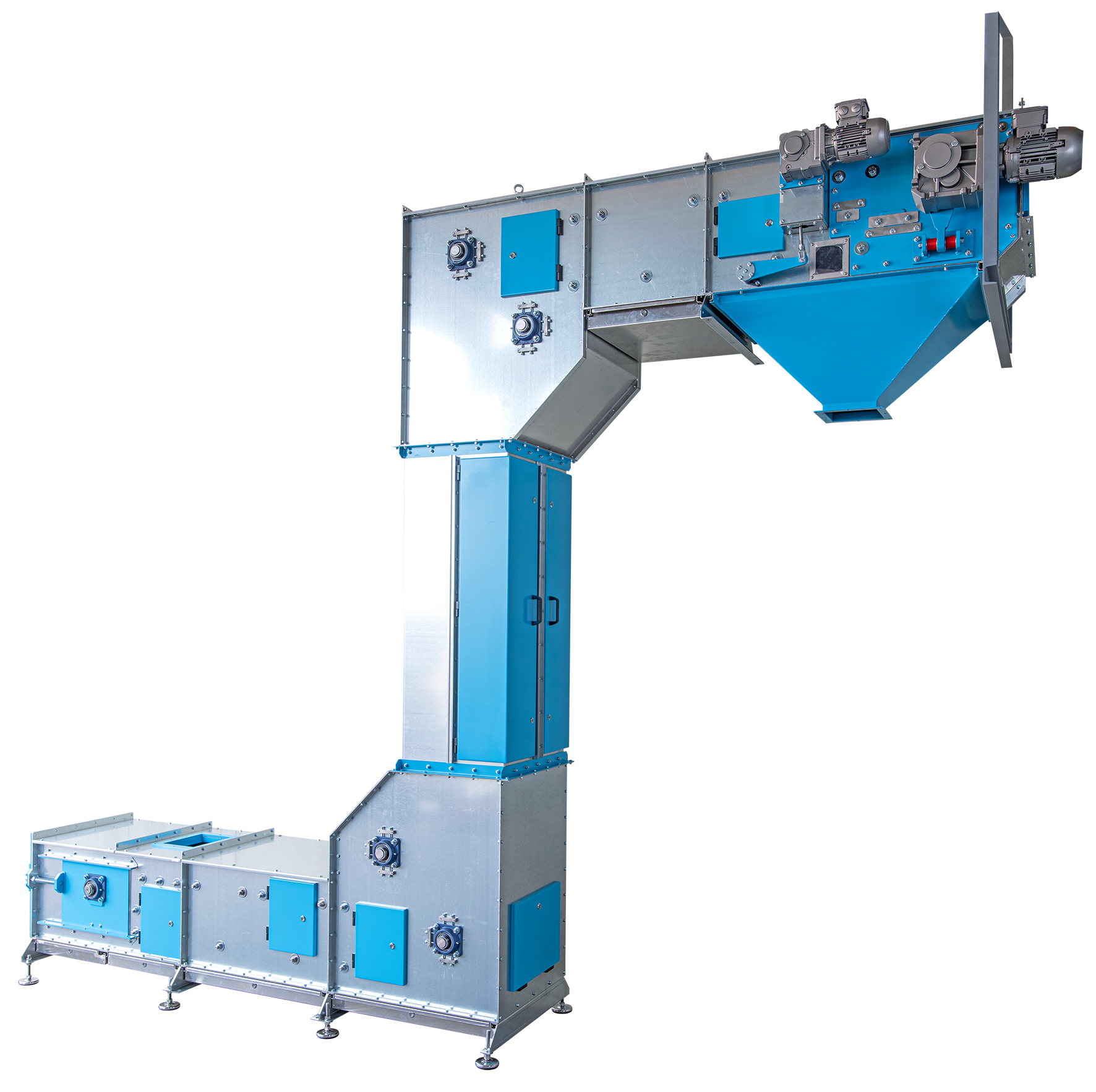

AREAS OF APPLICATION Such conveyor systems are mainly used in the food and chemical industries. The pendulum bucket elevator is suitable for filling silo systems, multi-head weighers or packaging machines. Such systems are used when multiple deliveries are required and with extremely individual lines. The pendulum cups always hang with the open side up during transport, so that no product is lost - regardless of whether it is conveyed horizontally, vertically, upwards or downwards.

ADVANTAGES

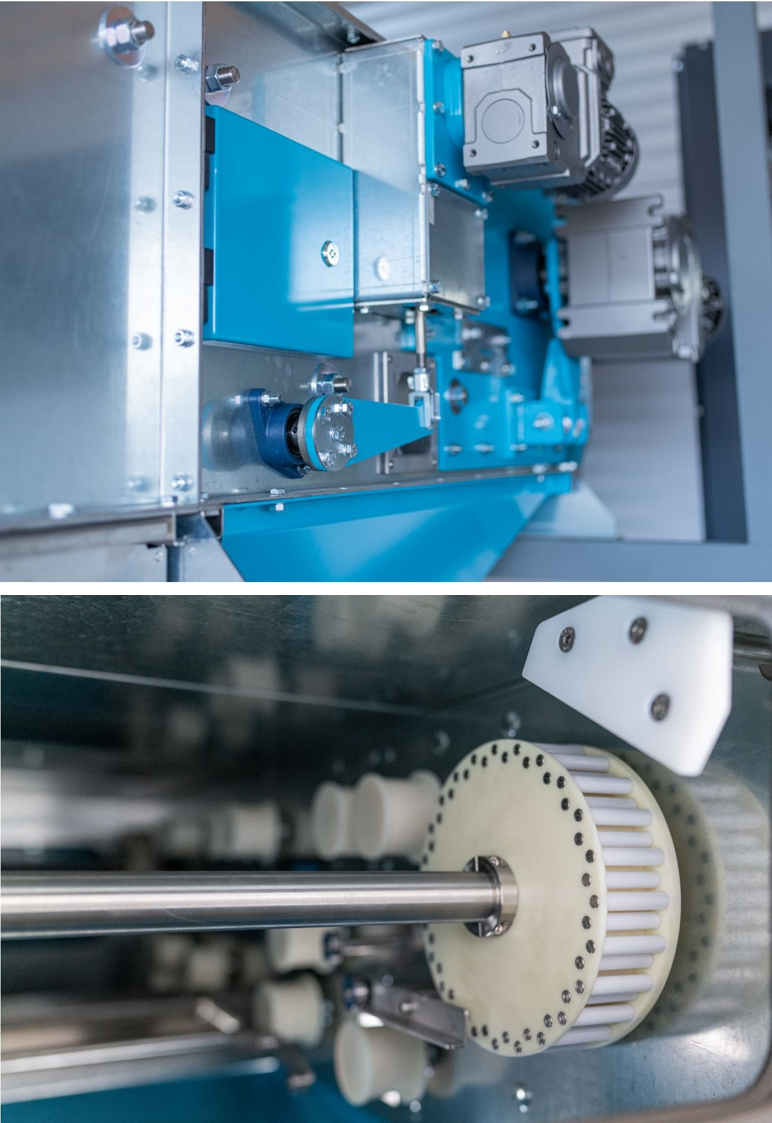

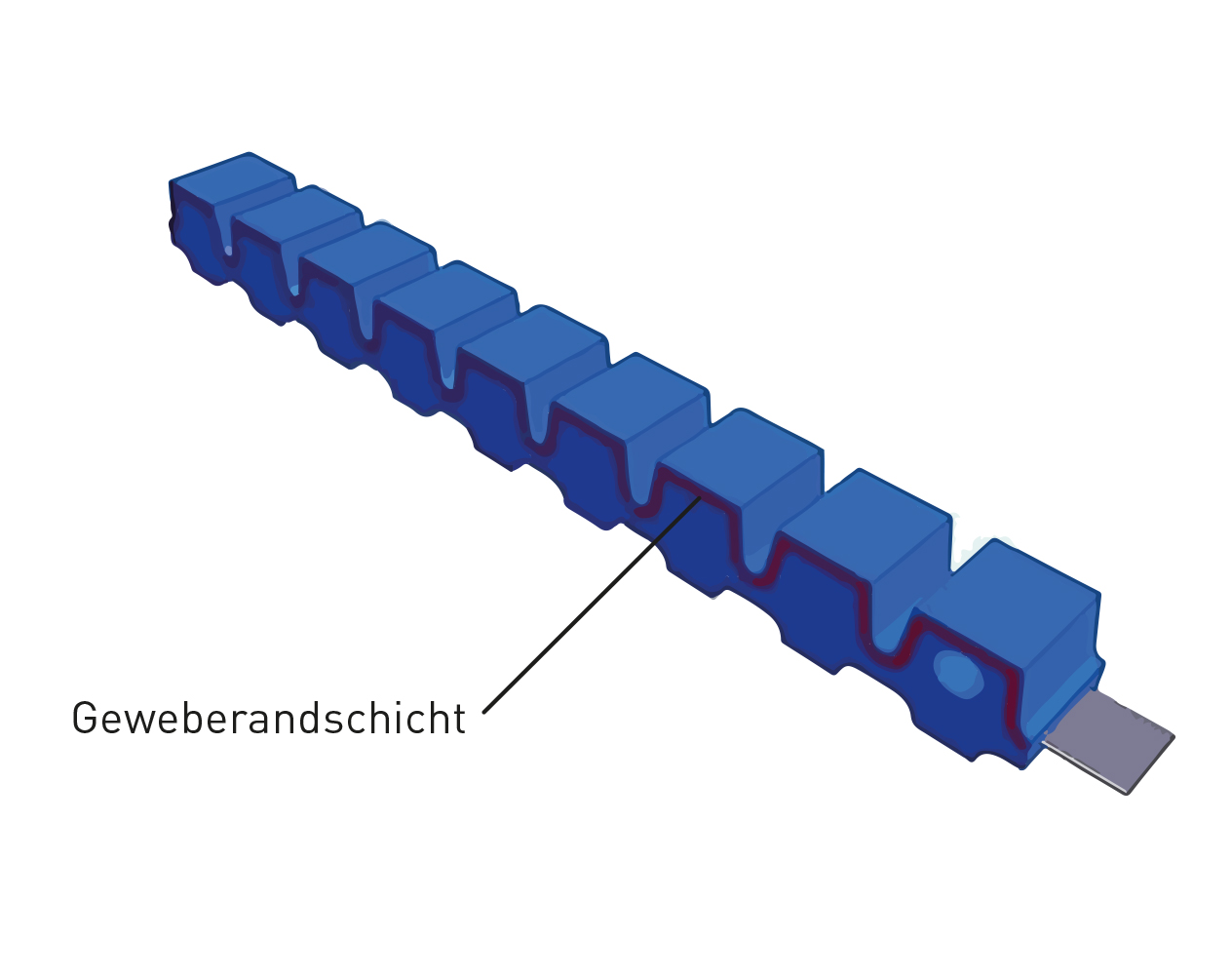

RUBBER BLOCK CHAIN The use of the rubber block chain ensures particularly quiet running and low wear. The workplaces that are in the immediate vicinity of the conveyor are therefore not affected by annoying running noises. The rubber block chain enables extremely cost-effective operation, as lubrication, regular adjustment work and re-tensioning of the chain are not required, and maintenance costs are reduced to a minimum. The material of the rubber block chain can be adapted to the respective application and the respective product. The high tensile strength is achieved through the use of vulcanized Kevlar and special fabrics. In addition to the advantages of the hinge-free, low-noise, wear-resistant and maintenance-free operation, there is a stable quality aspect: a corrosion-free design.

PENDULUM BUCKET Plastic was chosen as the base material for the cup, which is also available in a detectable version. Most media in food and chemical industries can be transported with this material.

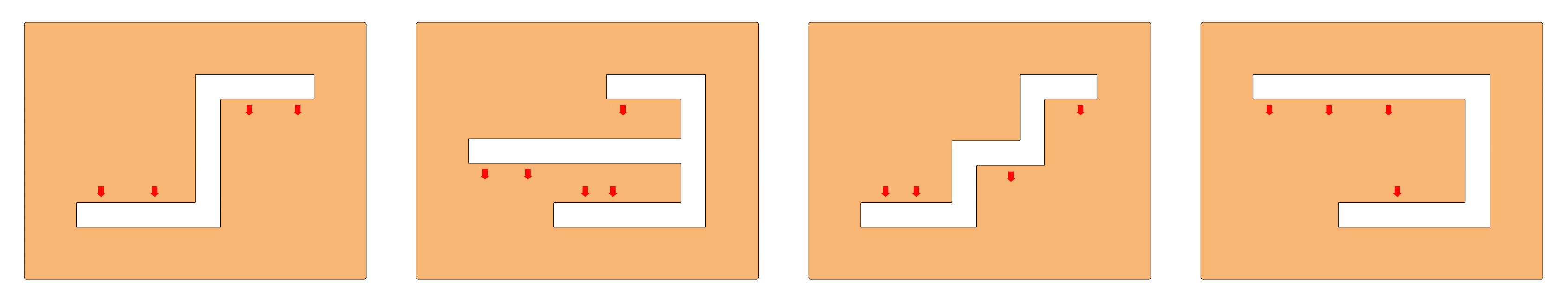

POSSIBLE DESIGNS

|